Information management in shipbuilding projects – Information flow from 3D design to production data

WHITE PAPER

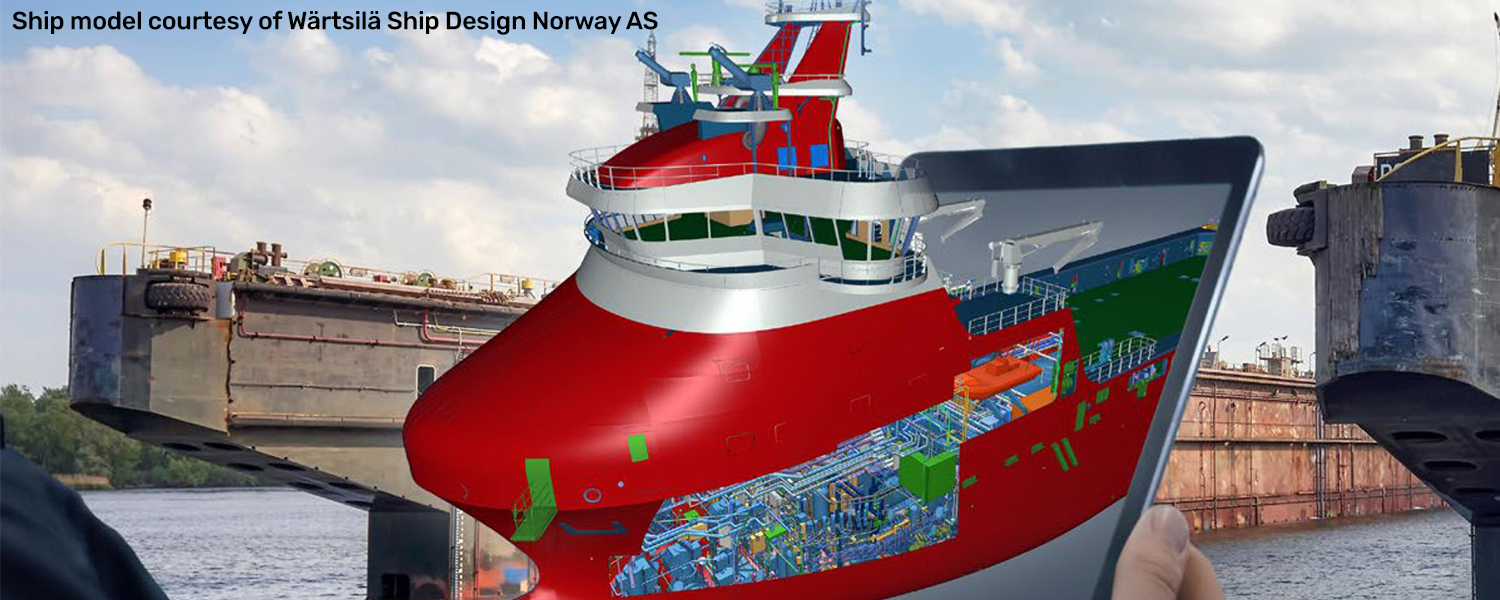

The shipbuilding projects require a particular approach to the ship design process, extensive information for manufacturing, and a carefully designed information flow of data between these phases. In an ideal situation, the complete shipbuilding lifecycle solutions would support incremental creation and the use of data from one phase to another. Data refers to the 3D CAD model of a complete vessel and all of its parts: hull, structure, equipment, piping, outfitting, electrical cables, and linked engineering data from results of a simulation, electrical load calculations, as well as engineering bill of materials and production data to facilitate manufacturing, pre-outfitting, and assembly. In reality, this process in the modern shipbuilding environment is highly fragmented regarding stake- holders, work processes, and supporting IT systems. These include organization and network structures, used digital solutions systems and preferences for data formats, collaboration mode, and the scale of digitalization. Existing academic research mainly focuses on the theoretical implications of ship design as a product – highlighting its functional characteristics and partially economic profitability. The practicalities of shipbuilding process design and implications of workflows, management, and information flow design are often guarded as internal information, as they significantly impact shipyards’ competitiveness.

This paper looks at information flow between two phases of the shipbuilding lifecycle – design and production - and highlights practical possibilities to gain efficiency by eliminating information flow gaps and placing data in the context.